At Vertech Group, we pride ourselves on fostering a culture that promotes innovation in all aspects of our work. A crucial part is seeing a problem and striving to create a solution.

Over the last decade, our engineers have experienced the frustration of conventional inspection reporting methods and have actively tried to improve the process. The creation of our SONO-E, ViiPER and SIMS specialised digital reporting systems are just some of the ways our teams have made reporting easier and more efficient.

SONO-E Reporting

The SONO-E Reporting System is a bespoke e-reporting tool that allows our technicians to report from the site in real time, giving our clients instant access to the results of an inspection.

SONO-E is fully optimised, allowing it to be used on multiple devices, including mobile phones and tablets. Reports are compiled upon job completion and then digitally approved by our QA coordinators.

Following QA approval, an auto-generated alert is emailed to the client, allowing them to access the report and any attachments immediately.

Having purpose-built the reporting system to be cloud-based, our engineers, technicians, and, more importantly, clients can facilitate and monitor all NDT reporting online in real time.

The SystemSystem is also fully customisable to suit the needs of individual clients, with features such as editable reporting templates or invoicing capabilities included upon client request.

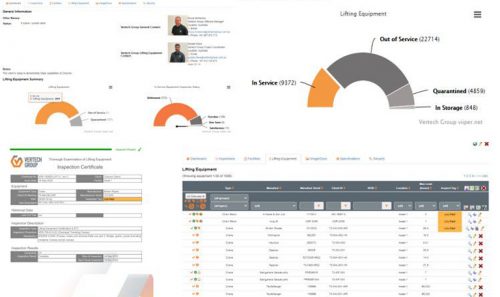

ViiPER

A major obstacle in lifting campaigns is the intense administrative and management burden of maintaining compliance registers.

Our onsite teams regularly found that multiple revisions of a spreadsheet could be in circulation at any one time, often resulting in repeated work or errors being made. Rather than suffer the issue, the Vertech team sought to develop their own more efficient method, creating the ViiPER management system.

By consolidating all data for each piece of lifting and safety equipment through their complete life cycle in a single online platform, our team has achieved an 80% reduction in reporting time on select scopes and reduced risk to people, processes and plants from lifting equipment failure.

SIMS

SIMS has been developed to close the gap between inspection and integrity-related activities by streamlining work scope development, data collection, data analysis, statistical analysis and evaluation.

While this makes the inspection process much more manageable, our development team also wanted to allow clients to view the data more efficiently. It also developed an interface that could express the inspection data through the realisation of a digital twin.

This SystemSystem has proved invaluable, with teams worldwide using it on countless NII campaigns, often resulting in significant cost and safety benefits for the client.

Contact Vertech Group

While Vertech Group has extensive experience with our bespoke reporting systems, having the flexibility to work with standardised reporting systems is critical to offering a well-rounded service to the client.

When specific scopes were required, our onsite and office team worked with programs such as Argonaut, Ship Manager Hull, Meridium, and Pegasus to summarise the inspection data and report it to clients.

Vertech Group aims to be at the forefront of innovation, regardless of the reporting system.