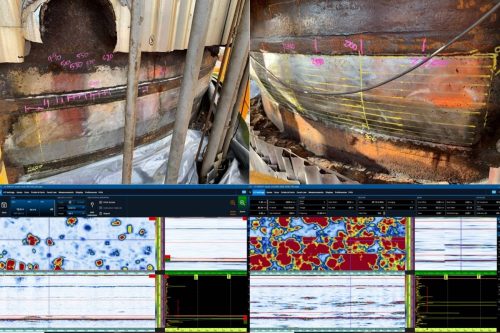

Sonomatic completed a detailed inspection to detect high-temperature hydrogen attack (HTHA) on vessels using phased array ultrasonic testing (PAUT). HTHA was not detected in this campaign, but hydrogen-induced cracking (HIC) was identified in the heat-affected zone (HAZ) of the head-to-shell weld of one vessel.

HTHA Shutdown

What is HTHA?

High-temperature hydrogen attack (HTHA), also called hot hydrogen attack, is a problem that can impact steel operating at elevated temperatures (typically above 400°C) in hydrogen environments, in refineries, petrochemical and other chemical facilities, and, possibly, high-pressure steam boilers.

The main factors influencing HTHA are the hydrogen partial pressure, the steel’s temperature, and the duration of the exposure.

HTHA results from hydrogen dissociating and dissolving in the steel, then reacting with the carbon in the steel solution to form methane. This can result in either surface decarburisation, when the reaction mostly occurs at the surface and draws carbon from the material, or internal decarburisation, when atomic hydrogen penetrates the material and reacts with carbon to form methane, which accumulates at grain boundaries and precipitate interfaces and cannot diffuse out of the steel. This causes fissures and cracking, which are typical of HTHA.

Inspecting for HTHA

An HTHA campaign is one of the most challenging non-destructive testing (NDT) inspections relying on correct technique selection, operator competency, and experience. The most suitable techniques for HTHA inspections depend on the specific inspection area. It is widely recognised that inspection procedures using a combination of PAUT using advanced acquisition algorithms such as total focusing method (TFM) and time-of-flight-diffraction (TOFD) ultrasonic methods are fundamental for achieving a robust inspection regimen for HTHA assessment.

SPEAK TO VERTECH GROUP ABOUT YOUR NEXT PROJECT

"*" indicates required fields