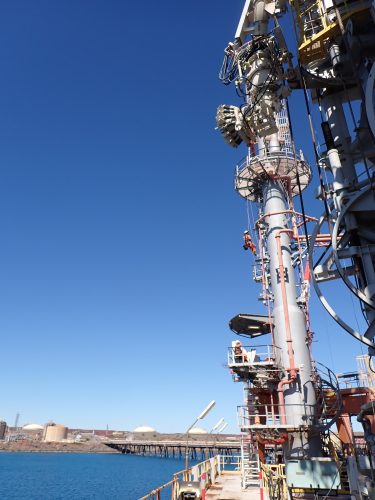

Vertech teams commenced ongoing piping zone and pressure equipment inspections across a major LNG asset in Western Australia in 2021. The scope of works included process and utility piping, including valves and fittings, pressure vessels, columns, serially produced vessels (gas cylinders, accumulators), heat exchangers and atmospheric and low-pressure storage tanks.

LNG Core Pressure Equipment Inspection

Process safety requires effectively installing operating barriers for pressure equipment to prevent or mitigate incidents. However, degradation mechanisms can reduce the integrity of barriers over time. Inspection to the client standards and in line with AS 3788 is required to assess and verify the physical condition and integrity of obstacles, reducing the risk of harm to people, equipment, and the environment through potential loss of containment.

Scope Requirements

- Coating system inspections

- Scab or blister assessments (HOIS-G-028)

- Corrosion Under insulation (CUI) inspection

- Passive fire protection assessment

- Flange, Bolting and Vale inspection

- Defect assessment and monitoring

- Trunnion Inspection & monitoring

- Pipe Supports and hanger inspection

- Identifying and monitoring galvanic connections

- Tertiary steelwork inspection

- Vessel and storage tank inspections

- Pressure piping inspections (AS 3788)

- Rope Access & Robotic inspection

- Turn Around Inspection & Access Support

Team Competencies & Expertise:

- AICIP In-service Inspectors

- Senior AICIP In-service Inspectors

- Multi-Disciplined NDT Inspectors

- Unmanned Aerial Vehicle (UAV) Pilot(s)

- Remote Digital Visual inspectors

- IRATA Rope Access Level 3’s

- IRATA Site Supervisors

- STOPAQ competent Installers

- Advanced NDT Inspectors

Contact Us to Find Out More:

"*" indicates required fields