Vertech was decommissioning the North Rankin Derrick, a drilling derrick on an offshore production platform, whilst the platform was operational. Vertech provided planning, engineering and technical services, completed onshore mock-up trials, and managed multi-disciplinary rope access personnel to complete this challenging project successfully.

North Rankin Derrick Decommissioning

Project Planning

The Vertech project management team worked closely with engineers and management teams from Transfield Worley and Alliance Engineering (AEC) to review every phase of the project execution. The site team deployed to complete NDT inspections, electrical inspections, UAV surveys, and visual and dimensional surveys. Over months, this careful planning and collaboration between each contractor reaped significant benefits as we identified areas of challenge we could engineer, identified regions where specialist tooling or specialist access systems would add for greater efficiency and safety performance, and ultimately modelled and sequenced each lift.

On completion of the project planning phase, a comprehensive mock-up trial with all IRATA supervisors and rope access tradesmen who would mobilise was conducted using the HIAB-mounted crane to familiarise the teams with each piece of equipment and simulate the scenario offshore. This level of pre-planning and training was a significant factor in this project’s safe and successful completion.

Solution and Results

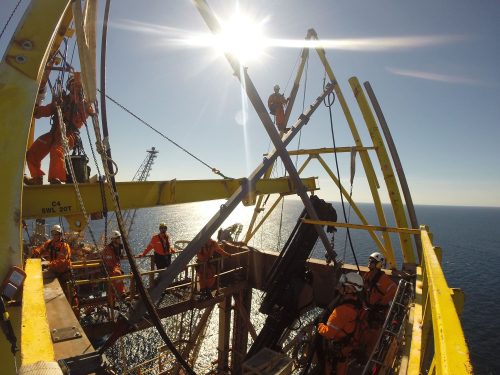

In the practical delivery, Vertech provided technical rigging solutions using a Hi-Ab crane mounted on the derrick guide rails and welding and cutting, fitting, and electrical trade services. The engagement of a multi-skilled and highly motivated team was crucial in successfully deconstructing the derrick, allowing for 20 multi-skilled personnel to replace the proposed 41-man implementation crew.

We worked closely with key contractors such as Alliance Engineering and Transfield Worley to plan and sequence every component of the project, from the initial deconstruction and removal of all tertiary steel, electrical cabling and ancillary equipment moving onto stick deconstruct using a custom Hi-Ab crane and finally, to modular lifts and dual crane lifts all while the facility was still in full production.

The project was completed with a perfect safety record and included many innovations for effective delivery.

Woodside Energy - North Rankin Drill Derick Decommissioning