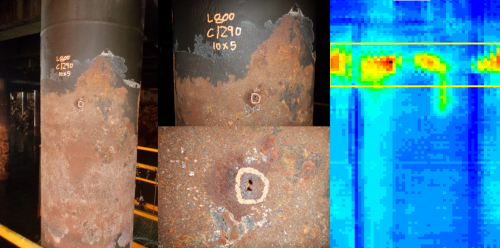

When Vertech and Sonomatic Australia collaborate on scopes, they draw on each other’s key strengths to deliver the very best service. In 2020, Vertech and Sonomatic used Nondestructive testing methods (NDT) to screen 300 steel jetty piles from the stock head to the water level (approximately 6m per pile) using the LYFT Pulsed Eddy Current (PEC) method to determine the extent of external corrosion. The team utilised several methods of access, including IRATA industrial rope access, a scissor lift, and a barge.

Pilbara Port Corrosion Mapping

By employing the LYFT array probe (PECA), Vertech Group could screen the full circumference of the pile in only four scan strips while still achieving a high level of data resolution. The inspection was completed on time (8-week campaign period), safely, and within budget.

What is Pulsed Eddy Current?

Pulsed Eddy Current (PEC) is a non-contacting electromagnetic inspection technique used to measure the thickness of carbon and low alloy steel through a range of non-conductive/non-ferromagnetic materials, including insulation, corrosion products, fireproofing and marine growth. As well as the singular PEC unit, Sonomatic also utilises the Lyft Pulsed Eddy Current Array (PECA), a probe that utilises six units operating in tandem. Covering a 457mm wide strip, this unit greatly increases productivity and reduces set-up time.

The Outcome

The team completed 100% scans on each of the 300 Steel piles, identifying numerous areas of corrosion and some areas of perforation that required remediation and future repair. The 360-degree corrosion maps provided for each pile have provided the client engineering and integrity functions with the necessary information to assess the structure’s integrity and future repair methodologies.

Speak to Vertech Group about Your Next Project

"*" indicates required fields