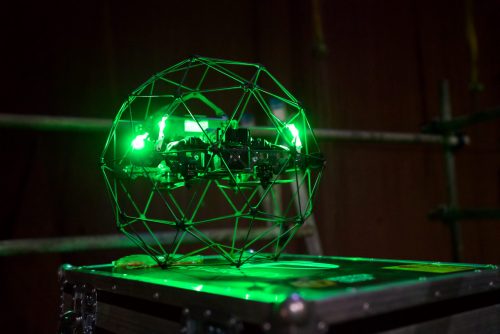

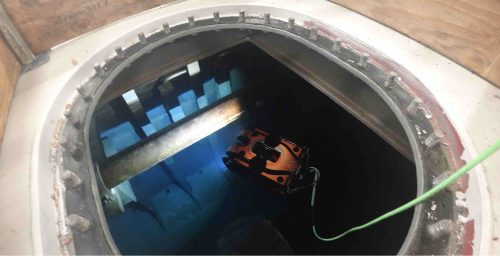

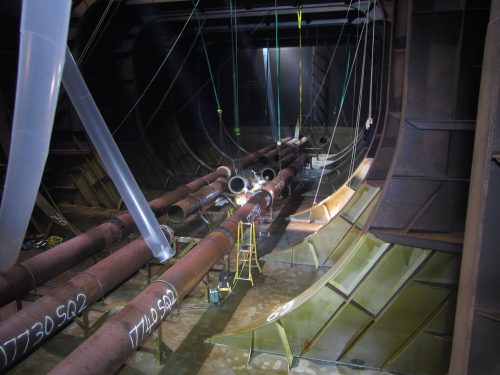

Vertech’s Marine Department is in a class of its own, providing industry-leading marine services. We are one of the only inspection providers in the southern hemisphere accredited by all major classification societies such as ABS, LR, BV & DNV for manned and unmanned inspection and integrity services, which includes UAVs and ROVs.

We pride ourselves on our proven track record of managing and delivering safe, innovative, high-quality inspection services.