Radiographic Testing (RT) is a non-destructive testing method of inspecting materials for hidden flaws by using the ability of short X-rays and gamma rays to penetrate various materials. It can be carried out on our clients' sites (under a strictly controlled environment) or within our Radiography bays.

Most radiography concerns the testing and grading of welds on pressurised piping, pressure vessels, high-capacity storage containers, pipelines, and structural welds. Other tested materials include welder's test plates, machined parts, plate metal, or pipe wall (locating anomalies due to corrosion or mechanical damage).

Radiographic Testing (RT) is a non-destructive testing method of inspecting materials for hidden flaws by using the ability of short X-rays and gamma rays to penetrate various materials. It can be carried out on our clients' sites (under a strictly controlled environment) or within our Radiography bays.

Most radiography concerns the testing and grading of welds on pressurised piping, pressure vessels, high-capacity storage containers, pipelines, and structural welds. Other tested materials include welder's test plates, machined parts, plate metal, or pipe wall (locating anomalies due to corrosion or mechanical damage).

We can carry out radiography in any of our seven purpose-built radiography compounds and on client premises under a strictly controlled environment. We can offer both conventional radiography and Digital Radiography methods. One of the advantages of digital radiography is that it does not require wet chemicals for processing, diminishing the need for chemical use and the associated hazards that come with that process. A smaller amount of radiation is necessary to produce a digital image than that needed to make a conventional film.

Small controlled area photography

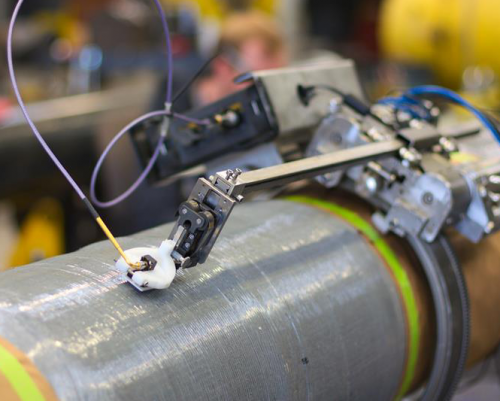

SCARPro source projector is used for industrial non-destructive testing applications of gamma radiography with Selenium-75. SCARPro can be used as a category I or II exposure device. When used in SCAR mode (category I), the SCARPro allows radiography to be performed in congested work areas with a minimal distance to the controlled areas. When used as a traditional projector (category II), standard Sentinel™ source guide tubes and collimators allow the Selenium-75 source to be used for axial, radial and panoramic exposures.

X-ray systems: OVDX – OpenVision™

Live video x-ray system enables real-time, qualitative screening for corrosion under insulation (CUI). CUI causes unscheduled downtime if not identified and corrected, posing significant cost and safety issues. Identify problem areas quickly, saving valuable time and resources. Scan miles with OpenVision™ versus mere feet accomplished by other NDT methods. OVDX effectively increases inspection productivity in refinery, pipeline and offshore environments. Video images and still image captures can be stored using a DVR.